Connect with GESAM KNUST on Facebook for Christian content updates and posts

GESAM in full is Global Evangelical Students and Associates Ministry, the Kwame Nkrumah University of Science and Technology chapter.

Learn more about Global Evangelical Church

This post details in depth the various things needed to make a wig either for personal use or for others, you'll learn other essential stuffs like preparation of abele walls and how to make liquid soap.

Wig making

A wig is the easily removable hair worn without it being weaved unto the hair of a person. It offers more flexibility since it is easy to remove and wear it any time without having to go through the stress of sitting in a hair saloon for hours for a weave-on or any other kind of time-consuming hair style. For people who desire flexibility in hair styling and have less time to spare for styling the hair, this is a very great option to try.

What is the difference between weave-on and a wig.

From the name, weave-on is actually weaved unto the hair which makes it fixed unto the hair. It can only be removed by removing the threads used in sewing it. Weave-on is like a direct attachment of fixation of either synthetic or any other form of hair kind unto the hair. Wing on the other hand is a very detachable or removable hair in that, it is worn as a hat without any difficulty at all. Once hair food is applied and brushed nicely, one is cool to go. People love to use this kind of hair type when they keep natural hair but when going to functions desire to look more cute among other reason.

Useful terms

Hair closure: For most hairs used to make a wig, there is a part of it known as the hair closure which has a net beneath it that is sewn at the frontal part of the hair net. This initial process of first sewing the closure serves as the foundation for the wig-making process.

T-pin: This is a type of pin that is designed in the shape or form of the letter 'T'.

C-pin: This is also a type of pin that takes the form of the letter 'C'.

Hair cap: It is a round cap that is worn on the head and has an elastic band to make it firmly fit the head.

Dummy head: A plastic sculpture piece molded in the like a human head with all the parts of the head like eyes, ears, nose and mouth. It aids in the wig-making process among other important uses in the hair dressing saloon.

Tools and materials for wig making.

- dummy head

- scissors

- thread

- C-pin or c-needle (curved as the letter 'C')

- T-pin

- wig cap

How to make the wig

Any type of hair capable of been used as a wig has this procedures applicable to it. Whether natural hair, synthetic hair (long or short), curls. Once all these necessary tools and materials above are ready, put the dummy head on a table or hold in between thighs whilst sitting to ensure it is stable for an easy process. Ideally, the dummy head has a hole beneath which is for fixing it unto a tripod that makes working with it easier. Wear hair cap onto the dummy head very nicely and accurately.

Fix hair net on the dummy using the T-pins. Position the hair closure with middle right above the nose of the dummy head. This ensures that there is accuracy throughout the whole process. Now the closure must be firmly fixed unto the dummy head by pinning it using the T-pin and then the process can continue smoothly. Thread the C-pin and sew the hair net and the hair cap at the frontal region to fix the closure onto the cap. This is the first part of the wig making process.

After this, the hair is sewn with the thread from the back of the head at the bottom.

Note: Some of the hairs are number, for instance, 18", 20' 22" 24" or even 8", 8", 8", 8". The smaller number indicates that is length is shorter and therefore must be sewn at the back and the highest number positioned at the top of head all the way to the frontal region. It is a way of ensuring that after the process of making a wig, there is equality in how the length of hair looks.

Closure successfully attached to the frontal part of the hair cap and the next process will begin

The edge of the hair roll is sewn using the threaded C-pin starting from the back and there must be an even distribution of space between the strand below and those upwards. The sewing is done by first creating a knot at the first point of penetration and hooking until strand finishes. The sewing is done in a way such that at any point in time a person can remove the thread from the wig and use the hair for another wig or improve on it if there happens to be some issues with it. Smaller spaces must be left at the middle of head getting to the frontal area to make it look thicker and attractive at those areas.

Importance of learning wig making as a skill

For easy access and convenience, having wig readily available helps in a lot of ways that you do not want to neglect.

With a wig available, any time there is an event that requires ones presence and things have to be done more quickly, there is no trouble getting things done fast especially the hair. About an hour or a little over this should be enough to do something like this and get it handy anytime for use.

If you are not really concerned about the services of a professional hair

dresser and wants to save money, consider something like this and serve some money for other needs.

- The making process keeps you engaged in some creative activity

It is amazing to know that this process also employs creativity as it is being carried out meaning it can keep the mind actively engaged in some creative process.

- It can be sold out for others who might not have the time to make one

Are you the one concerned about some business opportunities and market demands to supply and get some income flowing in towards you? This is a cool venture that can pay some bills.

What is abele walls?

This product is famous in some regions of Ghana if not all the regions and in the bid to understand the reason behind the fame, some interactions with people especially some consumers unraveled some interesting stories. The Gas call maize 'Abele' and it is one such food product that is very known in the area. It is like food products from maize are very appreciated by the folks and hence giving fame to the word abele. One consumer said an ice cream at the time was been sold in the region which assumes the form of a wall and as this also gained some popularity, the people began to associate abele to it and it later got very popular in other places. Abele wall is an ice cream that tastes very fantastic and it is great having one for a desert or party.

Ingredients for make abele walls

- hard flour

- milo, milk

- margarine

- milk powder

- condensed milk

- vanila essence

- strawberrry flavour

- banana flavour

- food colouring pigment or solution,

- disposable cups,

- sugar.

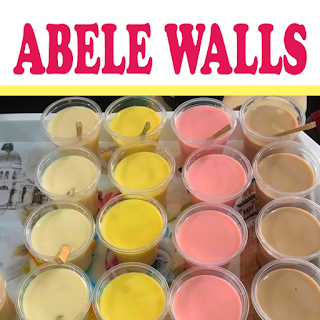

Some of the ingredients are shown here

Some of the ingredients are optional though depending on the preferences of the one making it..

How to make abele walls

Pour water into a pot and put it on fire to boil.

Mix flour with water into an even mixture and pour into boiling water. Stir thoroughly to make a porridge .

Learn more about corn powder porridge preparation

Allow to cook very well and add a small amount of margarine. The margarine helps to add a nice smell to the hard flour porridge and also reduce the flour taste that might be present in the porridge.

Mix milk powder into water into an even mixture and add condensed milk to mix thoroughly. Pour porridge into mixture of milk powder and condensed milk to mix again. Sieve to remove any lumps that might be present in the mixture. Add liquid milk to the sieved mixture and then add your sugar. The abele wall or ice-cream is almost ready now. As there are about four flavours available, the base mixture which is ready is divided into four.

For first division, add vanila essence only and this gives the all white abele walls or ice-cream. The vanila adds that nice scent to it.

Add chocolate to the second division. To get the chocolate flavour, cocoa powder is mixed with water and then added to get the chocolate flavoured abele walls.

Add strawberry to the third division for the pink looking abele.

Then lastly, add banana flavour to the last group and food colour of yellow colouration can be added and likewise for the strawberry a pink food colouring solution can be added.

The food colours must be added in small amounts to prevent over colouring of the ice-cream.

All four flavours of the abele mixture but there are more other flavours to explore

After this processes, the liquid abele or creams are poured into disposable cups and the abele sticks inserted. The filled disposable cups are then put in a refrigerator which is mostly a deep freezer to make the product become iced. To consume it, one has to only use the stick to pull out the ice-cream or abele walls and lick gradually to enjoy. Abele is a wonderful ice-cream with a fantastic taste that people produce and sell to customers who love it. You too can try some.

Liquid soap making

Liquid soap is useful for dish washing at home, hand washing in offices and other very important uses and applications. There are varieties of colours of liquid soaps available in the local markets and supermarkets. This session introduces the processes involved in making liquid soap for everyone. The ingredients used mostly are used in standard quantities to ensure proper preparation result and also prevent any side effect that might not be good.

Ingredients needed.

- Water

- Thickener - 250ml

- Booster - 250ml

- Perfume

- Booster rise

- Salt - 750g

- base gel

- colouring pigment

To prepare the soap, get a big bowl and pour some amount of water inside. Prepare a salt solution by pouring in the salt to stir as it dissolves. Make sure to stir in one direction throughout the whole process to prevent any undesired outcomes. Add base gel and stir to mix.

As the mixture is being stirred, water can be added in small amounts for a good thickness of the soap. Add thickener and booster rise. The colouring pigment can also be added. The soap is ready but at this point it might be so full of scum so it can be left overnight for it to settle before pouring into bottles. As the various ingredients are added and stirred, the mixture becomes more thicker and water must be added to make it loose and not be too thick.

At this stage green colour was added but due to the foam or scum it is mostly left overnight and it settles by itself before bottling

Comments

Post a Comment

Share your views on this insightful content